Thermographic analysis - Inspexi

Main menu:

- Home Page

- About us

-

Our services

- Our services

- Inspection and Testing

- Engineering and consultancy

- Our clients

- Contact us

Thermographic analysis

The use of infrared cameras began over 50 years ago with the inspection of high-

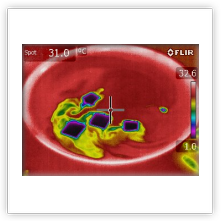

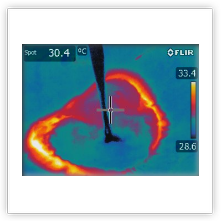

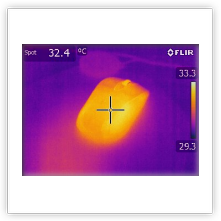

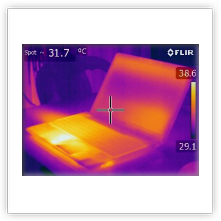

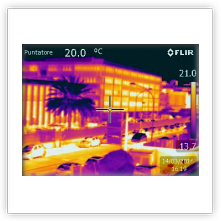

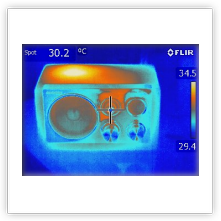

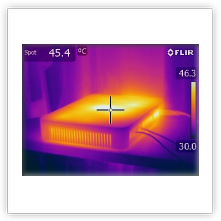

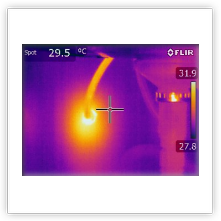

Infrared thermography helps detect abnormalities hardly visible to the naked eye, allowing you to take corrective action before they occur faults in systems with serious consequences, by displaying the distribution of the temperature of machinery and electrical devices, quickly, accurately, safe for the operator, thanks to the absence of contact with the object under examination.

Inspexi uses cameras with suitable characteristics to be able to work in different sectors, as Civil (construction) -

Ask for more information

Immages

Possible fields of application of thermography

Environment

Compactness control of glaciers and snowy layers for avalanche prevention

Land compact control to prevent landslides

Control of waste incineration process

Control of underground geothermal activity

Control of solid and liquid waste storage facilities to prevent leaks of pollutants in the soil

Thermal pollution detection of the seas, lakes and rivers due to industrial and civil waste

Control temperature changes in the sea waters, lakes and rivers

Locating underground magma channels

Locating missing persons in the woods, forests, mountains or at sea

Localization industrial discharges into streams, rivers, lakes and the sea

Thermal dams map

presence and movement monitoring animals in protected reserves

Monitoring of forest fires

Evaluation of biogas production in the waste disposal site

Verify the presence of the cavity in the trunk of trees

Check presence of thermal alterations caused by disease or pests in plants

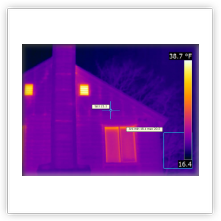

Building

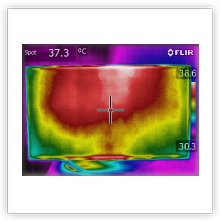

buildings analysis for the detection of defective insulation in the walls

Checks and heat loss controls for energy containment

Analysis of the stone sulfation processes

Identifying deterioration of concrete cover a.c. of road surfaces and coatings galleries

Identification of detached plaster

Identifying gaps covering the exterior and interior walls

Detection of water leaks from roofs and terraces

Detection of water leaks in subways, basements, tunnels

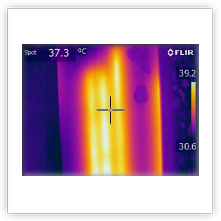

Identification of hot water leaks in pipes

bearing structures of buildings identification

Search of paths of hot water pipes and / or cold within walls or floors

Detection structure of building products under the plaster

Check waterproofing realized with the application of resins or tar paper

Check the presence of moisture in the outer walls and foundations

thermal map of the building structure to identify the nature of the material, humidity, occult lesions and peeling plaster.

Toothing between different walls, with relative reading of any added factory bodies.

Search of the positioning and sizing of structural elements such as exhaust arches, brick pillars, lintels

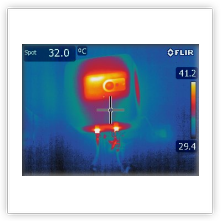

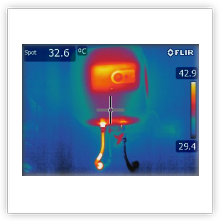

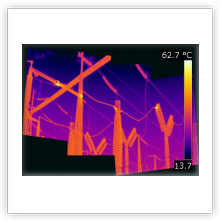

Electricity

operating temperatures of transformers Analysis

overtemperature detection caused by abnormal contact resistance of:

Electrical wiring on passers HV / HV, HV / MV, MV / LV power transformers

Power joints of insulated conductors

junctions

breakers

Terminals of HV and MV cables

various connector blocks

Switchboards Distribution

disconnectors

Check cogeneration plants

Check air transport lines

Check Ventilated busway lines and busway

Eectronics

Identifying defective components on electronic boards

Superficial thermal mapping of integrated circuits

Thermal dissipation optimization of electronic components

Distribution networks and transport of hazardous substances

Search for gas leaks along transport networks, distribution and storage tanks

Search of leaks in pipes and storage tanks

Production electricity distribution

Power lines

Check the possible presence of defects on cables, joints, tightening, insulators. production plants

Check large transformers.

Finding leaks in boilers.

Checking the thermal insulation in the boiler bodies. Electric cars

Investigations in alternators and electric motors

Control of bearings, supports and rotating parts to overheat

Industrial production facilities

Furnace insulation control

Chimneys isolation control

Reduced thickness control in pipes and high pressure tanks

Locating carbonaceous or calcareous deposits inside pipes for the transport of fluids or vapors

Measure temperature of the mantle of the ovens in cement works for the detection of anomalies in the refractory

Check wear of refractory linings for furnaces

Thermal distribution analysis during the blow molding processes of plastic bottles

Analysis of composite materials for the detection of discontinuities and defective bondings

Monitoring trends temperature inductive heating

Temperature control in the extrusion process of plastic films

Surface temperature control operating in petrochemical reactors

Control temperature uniformity of drying cylinders in the paper production

Control temperature uniformity of the molten glass prior to molding

Control uniformity of the glass temperature prior to the bending process

Detection of the product temperatures in continuous casting

Check temperature trend in rolling processes

Food industry

Thermal distribution in the control of food cooking ovens

Thermal control distribution in cold rooms for storage of frozen products

Temperature monitoring in production processes and food preservation

Check operation of compressors and condensers in industrial refrigerators

Heating and air conditioning

Control of heat exchangers efficiency for the detection of occlusions, insulation pipes

Check operation of steam traps

Machinery parts

Control moving parts and detection of overheating due to lack of lubrication and / or friction excesses

Checking the wear of the coupling devices

Overheating detection for wear or lack of lubrication in bearings and gear motors

Check operation of compressors

Check operation of the vacuum pumps

Check operation of chain drive systems

Check function of drive systems trapezoidal belts

Transport

Operation Analysis of ventilation and internal air conditioning systems to cars

Systems analysis operation for cooling in internal combustion engines

Temperature analysis in aircraft engines

Analysis of temperature variations during testing tires on test benches

Thermal variations of braking systems Analysis

Temperature measurements of contact lines for trains, trams, metros and trolleybuses

Temperature measurements of electrical motors, heaters, accumulators, compressors, bearings, hubs and brakes for trains

Temperature measurements of pantographs of trains, trams, metros and trolleybuses

Verify the presence of water infiltrations inside the composite materials of aircraft and boats

Civil protection

Protection by volcanic eruptions

Continuous monitoring of at-

Day and night views of the smoke and poisonous gases emitted by fumaroles. Industrial Risk Protection

Research of gas or hazardous liquid leak

Flue gas emission control

Thermal mapping of the coasts exposed to industrial risk

Search for missing persons in the dark or submerged by thin layers of snow

Other applications

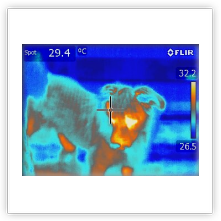

Muscle or joint inflammation detection

Detection of pathologies related to body movement

Mapping of body temperature

Night environmental surveillance